Used Widely Metal Cutting Cold Saw for Furniture Pipe Profile Pipe and Others

Used Widely Metal Cutting Cold Saw for Furniture Pipe Profile Pipe and others Brief Introduction on Metal Cutting Cold S

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | MC-425CNC |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Precision | High Precision |

| Certification | CE, ISO 9001 |

| Condition | New |

| Name | Metal Cutting Cold Saw |

| Technical | Cold Cutting |

| Blade Size | 425/400mm |

| Language | Multi Language |

| Feeding Way | Servo Motor Feeding |

| Cutting Type | Wet Cutting |

| Head Driven | Full Gear |

| Applicable Shape | Round,Square,Rectangle,Oval,Profile |

| Applicable Material | Ms.Ss,Copper,Aluminum |

| Voltage | Can Be Customized |

| Color | Standard or Customized |

| Cooling | by Fan |

| Controlling | PLC+Touch Screen |

| Machine Driven | Electric+Hydraulic |

| Company Type | Manufature |

| Transport Package | Wooden Case |

| Specification | 130x5mm |

| Trademark | SZ-SLS |

| Origin | China |

| HS Code | 846150 |

| Production Capacity | 500 Pieces/Year |

Product Description

Brief Introduction on Metal Cutting Cold Saw

SLS automatic pipe cutting machine with function of hydraulic clamp,servo motor feeding and hydraulic cutting.Automatic feeding ensure high cutting accuracy and increase productivity.Good mechanical system ensures high cutting quality without burrs on tube internal and external. Water cooling and lubricate system prolongs the life of machine and saw blade. Each cold saw machine is covered by a one year parts warranty plus lifetime technical support by SLS.We keep many cold saw models in stock for quick shipments.

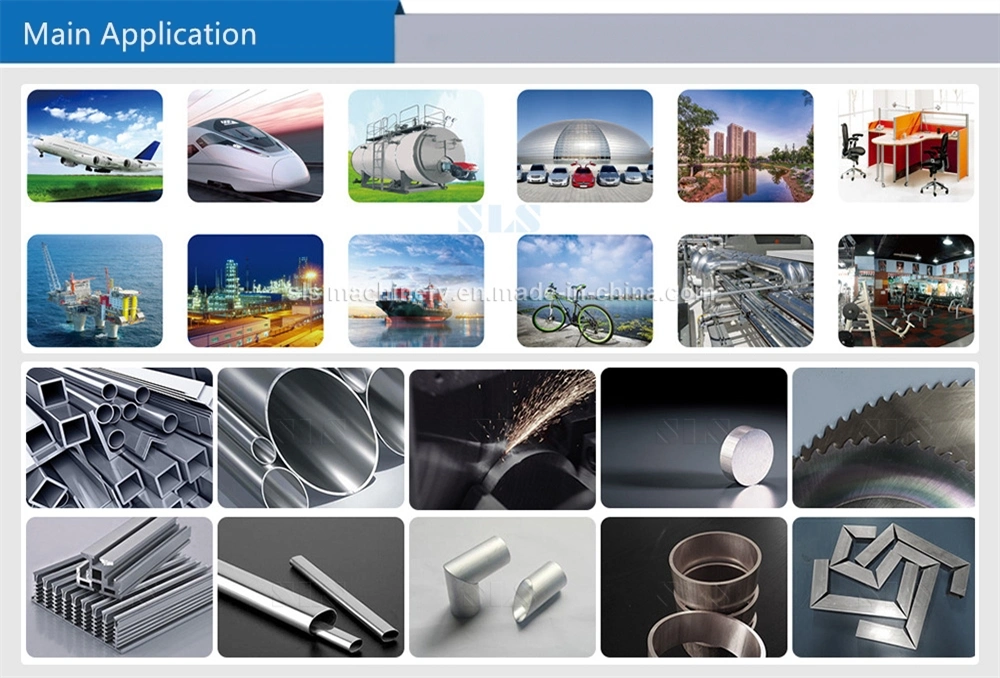

Features on Metal Cutting Cold Saw

Automatic Servo Motor Feeding,Automatic Hydraulic Clamping and Automatic Hydraulic Cutting.

Rigid cast iron saw bases and electro-welded steel frames maintain accuracy and minimize vibrations, even at full capacity.

Material of tube cutting machine is available:Steel&Stainless Steel.

Cutting Shape Available: Round,Square,Rectangle and other profiles.

Available for several pieces cutting together for small pipe size.

2 sides and 2 way clamping system: High precision cutting, reduce vibration and soundless while cutting.

Clamping, saw blade advancing,backward, clamp releasing are all hydraulic driven.

Good mechanical parts ensure machine runs in high stability.

CE, ISO9001 Certification.

Main Technical Parameters SheetModel MC-425CNC _ Max. Cutting Capacity ¢130×5mm _ Cutting Angle 90° or Angle Cutting _ Feeding Length Max 1500mm or Customized _ Servo Motor Power 1Kw _ Controlling PLC(Japan Mitsubishi) _ Motor Power 3.3/4.0Kw _ Feeding Accuracy +/- 0.1mm _ Clamp Way Front Back/Up Down _

FAQ:

| 1 Q: Are you a manufacturer or trading company? | A: Yes, we are a manufacturer.We are focusing on metal pipe/tube processing machines production. |

| 2 Q:Where is the nearest airport to your company? | A: Wuxi Airport or Shanghai Airport. |

| 3 Q: How to choose the pipe/tube cutting machines? | A: You have to inform us following details:- Pipe Outdiameter Range- Wall thickness range- The pipe material- Cutting Length- Pipe Original Length- Production Volume- Other requirements |

| 4. Q: Do you have CE certificate? | A: We have CE certificate. |

| 5. Q:How about your service? | A: Before Sales Serive: 1. We will help our customer confirm the right model according to the offered pipe inforamtion.2. Welcome to visit our factory to see our machine and our workshop before you place an order. After Sales Service:1. We provide manual book,detailed machine installation,commissioning video for help you correctly operate machine.2. We provide free installation,commissioning and training at our factory.If you need engineer go to your factory for machine installation, air tickets,food,hotel, local transportation shoule be at your account.3. Any problems on machine,we will reply you by email/tel or other online contact within 24 hours. |

Related Products

-

![2022 New Professional 16X20 Manual Double Station T Shirt Heat Transfer Press Machine Estampadora]()

2022 New Professional 16X20 Manual Double Station T Shirt Heat Transfer Press Machine Estampadora

-

![Portable Mini 30W 50W Fiber/CO2/3W 5W UV Laser Marking Machine/Laser Printer/3D Logo Printing Machine/Laser Engraving Machine for Metal/Jewelry/Plastic/Glass]()

Portable Mini 30W 50W Fiber/CO2/3W 5W UV Laser Marking Machine/Laser Printer/3D Logo Printing Machine/Laser Engraving Machine for Metal/Jewelry/Plastic/Glass

-

![Steel Security Door Main Entry Entrance Front Doors Design for Residentialy Exterior Others Door for Houses]()

Steel Security Door Main Entry Entrance Front Doors Design for Residentialy Exterior Others Door for Houses

-

![Drawer Type Multi-Function Aluminum Flatbed Heat Press]()

Drawer Type Multi-Function Aluminum Flatbed Heat Press